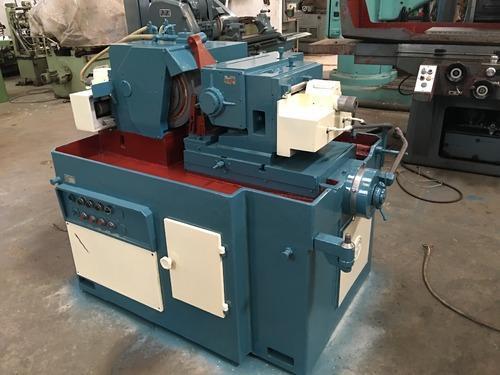

Centerless Grinder

उत्पाद विवरण:

- के लिए इस्तेमाल किया गया औद्योगिक

- मशीन का प्रकार केंद्रहीन ग्राइंडर

- शर्त इस्तेमाल किया गया

- Click to view more

सेंटरलेस ग्राइंडर मूल्य और मात्रा

- 1

- , यूनिट/यूनिट

- यूनिट/यूनिट

सेंटरलेस ग्राइंडर उत्पाद की विशेषताएं

- औद्योगिक

- केंद्रहीन ग्राइंडर

- इस्तेमाल किया गया

सेंटरलेस ग्राइंडर व्यापार सूचना

- 3 दिन

- ऑस्ट्रेलिया, दक्षिण अमेरिका, पश्चिमी यूरोप, मिडल ईस्ट, मध्य अमेरिका, एशिया, पूर्वी यूरोप, उत्तरी अमेरिका, अफ्रीका

- गुजरात, कर्नाटक, मध्य प्रदेश, महाराष्ट्र, तमिलनाडू

उत्पाद विवरण

Wide range of material can be worked upon using a Centreless Grinder. Volume manufactures depend upon this machine for producing components. A trained operator must operate this machine to avoid problems while working on a workpiece. Abrasive cutting is used for removing material from the workpiece. This process is different from centered grinding operations because it doesn't use any spindle or fixture for locating or securing workpiece. The workpiece is secured between rotary grinding wheels. Once the rate at which material is to be removed is determined, the operator has to set the speed of rotation of both grinding and regulating wheels. In a short time period, a Centreless Grinder can machine large batches of parts. The benefits of using a centreless grinding machine are many. Both, soft and brittle workpieces can be grinded by line wise support of the workpiece. There is no need to prepare workpiece for fixing in the machine. It is simple to load and unload workpiece. One can save time by using continues through feed grinding as no time is wasted for changing the workpiece. The operator can achieve high grinding wheel rotation speed.

Centreless Grinder :

- Make Cincinnati

- Model 325-20

- Grinding wheel size 600 X 500 mm

Specification

| Model Name/Number | 325-20 |

| Brand | CINCINNATI |

| Grinding wheel size | 600 x 500 mm |

| Weight | 18700 lb |

| Regulating Wheel Drive Motor | 3 HP |

| Regulating Wheel Speed | 300 RPM |

| Grinding Wheel Surface Speed | 10000 sfpm |

| Condition | Used |

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+